XPRIMER.WM - efficient management of production warehouses

and material flows in manufacturing

XPRIMER.WM is a reliable tool for efficient management of production logistics and warehouse operations.

Monitoring inventory levels of materials, semi-finished products, and finished goods, along with tracking material movements in XPRIMER.WM, forms the foundation for production cost optimization.

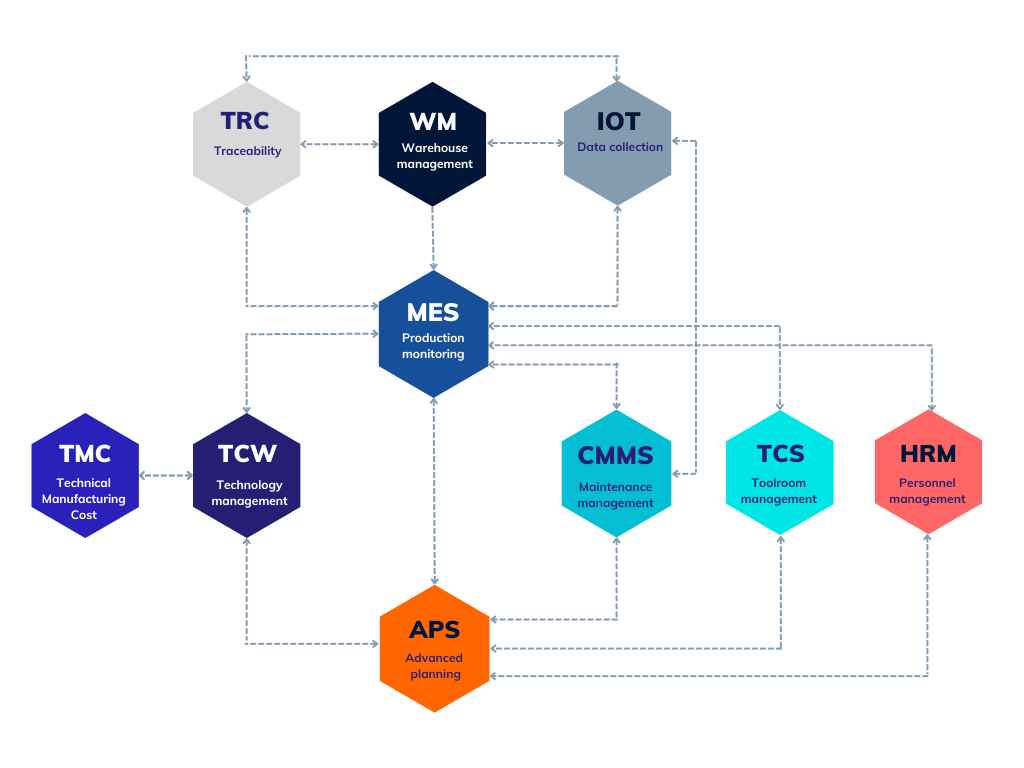

The XPRIMER.WM module not only enables the recording of every material movement in production but also integrates with the XPRIMER.MES module, providing comprehensive insight into production status. Furthermore, transactions in the WM module can be utilized for other processes, such as precise tracking of tool locations or fixed assets.

Synchronize production and warehouse processes with XPRIMER platform

Reduce operational costs

by automating inventory and material allocation processes, while reducing excessive stock on production lines or machines, order errors, and material overuse.

Boost process efficiency

through real-time monitoring of inventory levels across locations, warehouses, and machines, ensuring smooth production flow.

Enhance the flow of materials

utilizing data on material, raw material, and semi-finished product consumption, along with material demand requests for production.

Monitor work-in-progress

using real-time data on the actual status of materials, semi-finished products, and finished goods in specific production warehouses and/or allocated to individual machines.

Ensure full traceability

by tracking activities related to specific batches of materials, semi-finished products, and finished goods within production processes or warehouse movements.

Improve customer service

minimizing the risk of errors during order shipment and streamlining control processes at each stage of order fulfillment.

See what benefits our customers have gained by implementing XPRIMER

Read stories of customers who have streamlined their manufacturing processes with us.

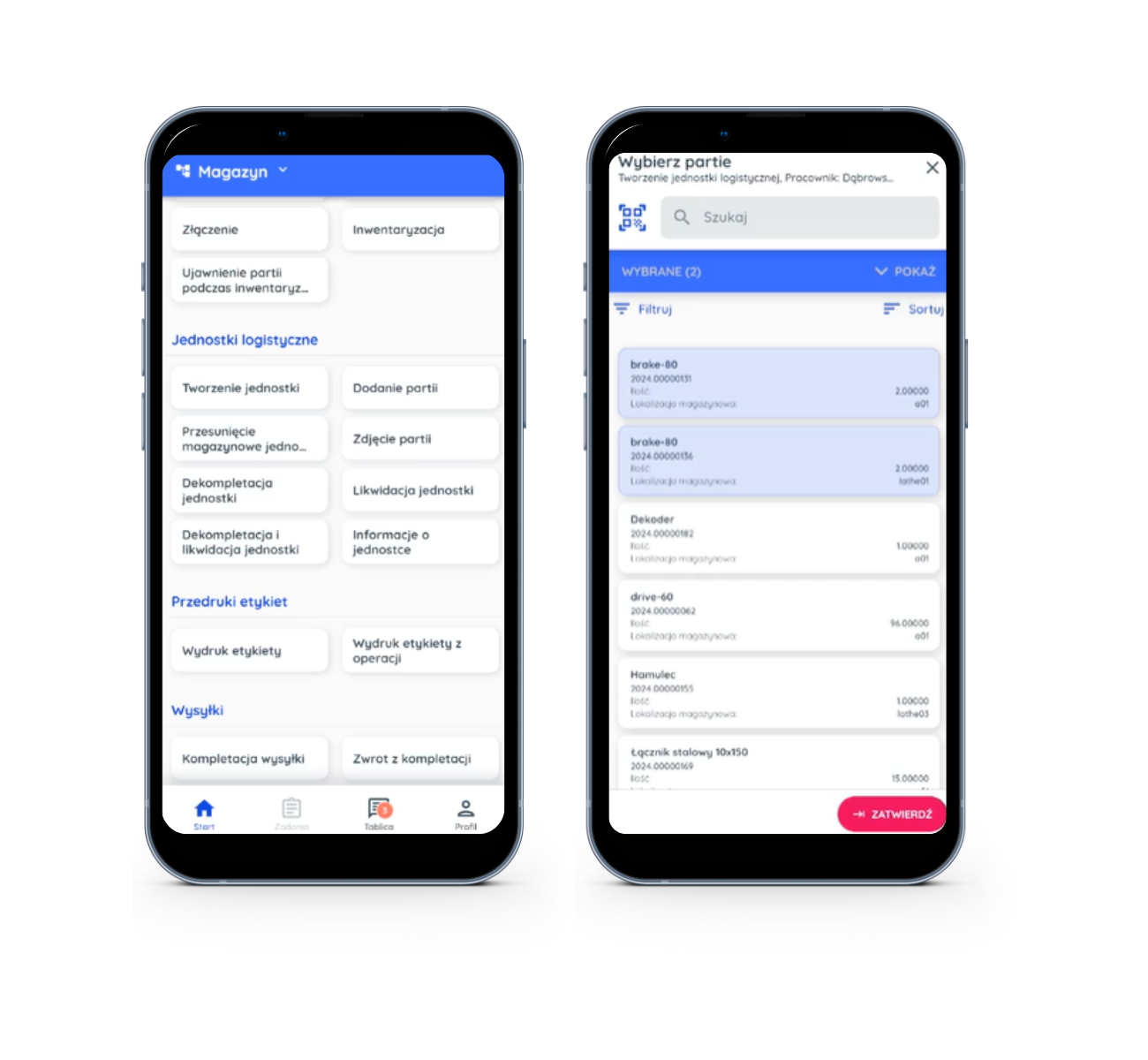

Explore the functionalities of XPRIMER.WM

Optimize material flows in production

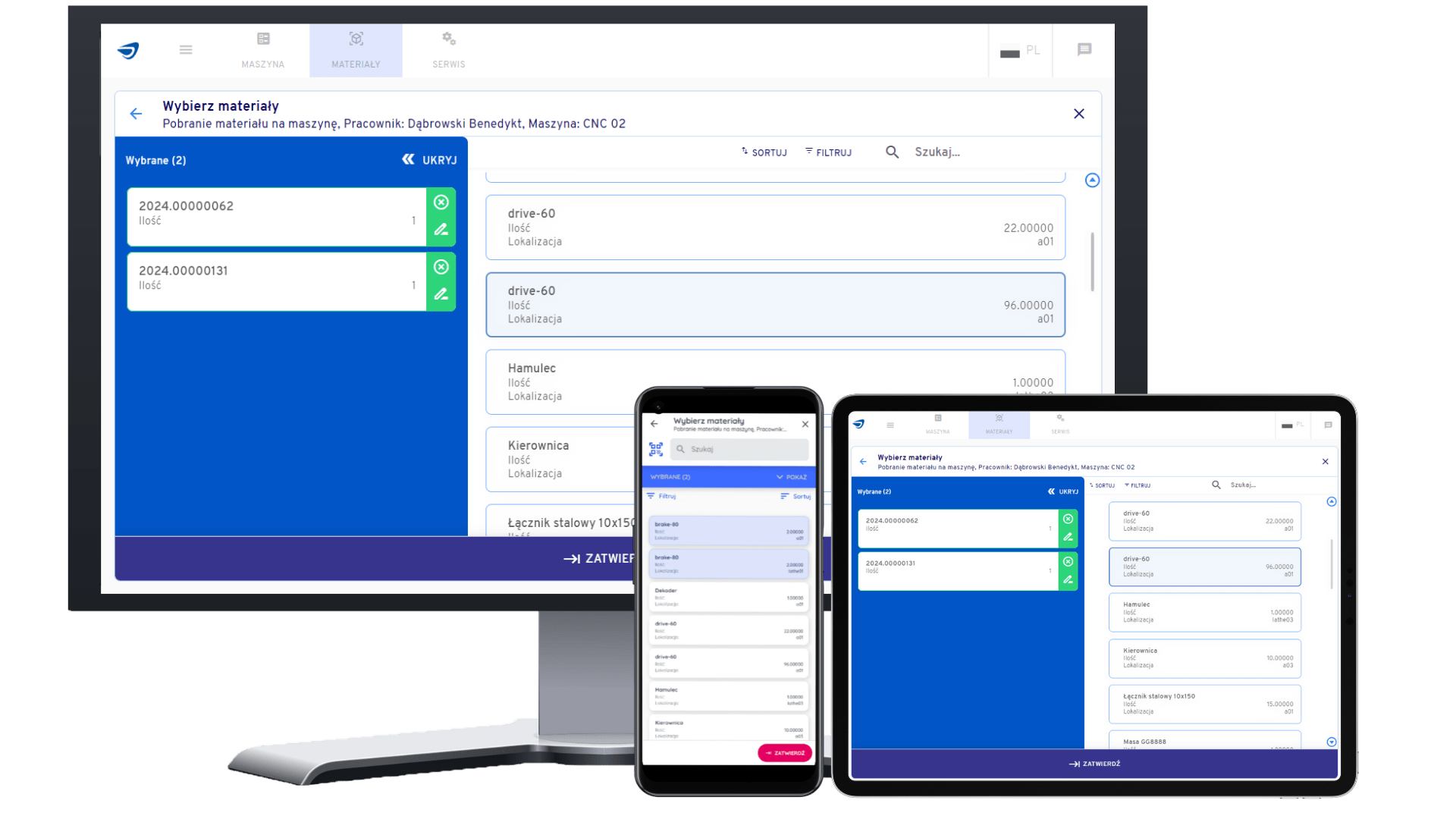

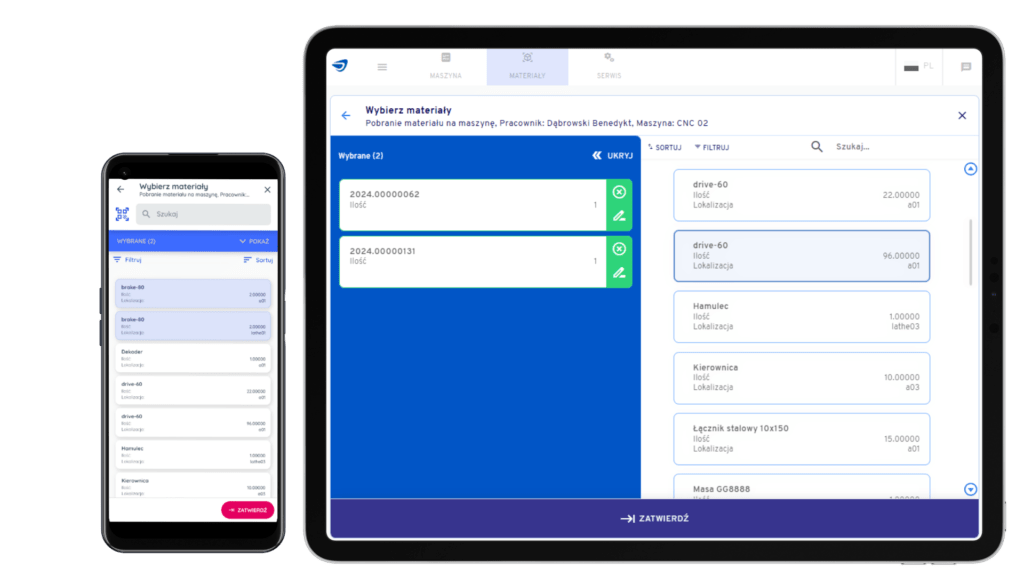

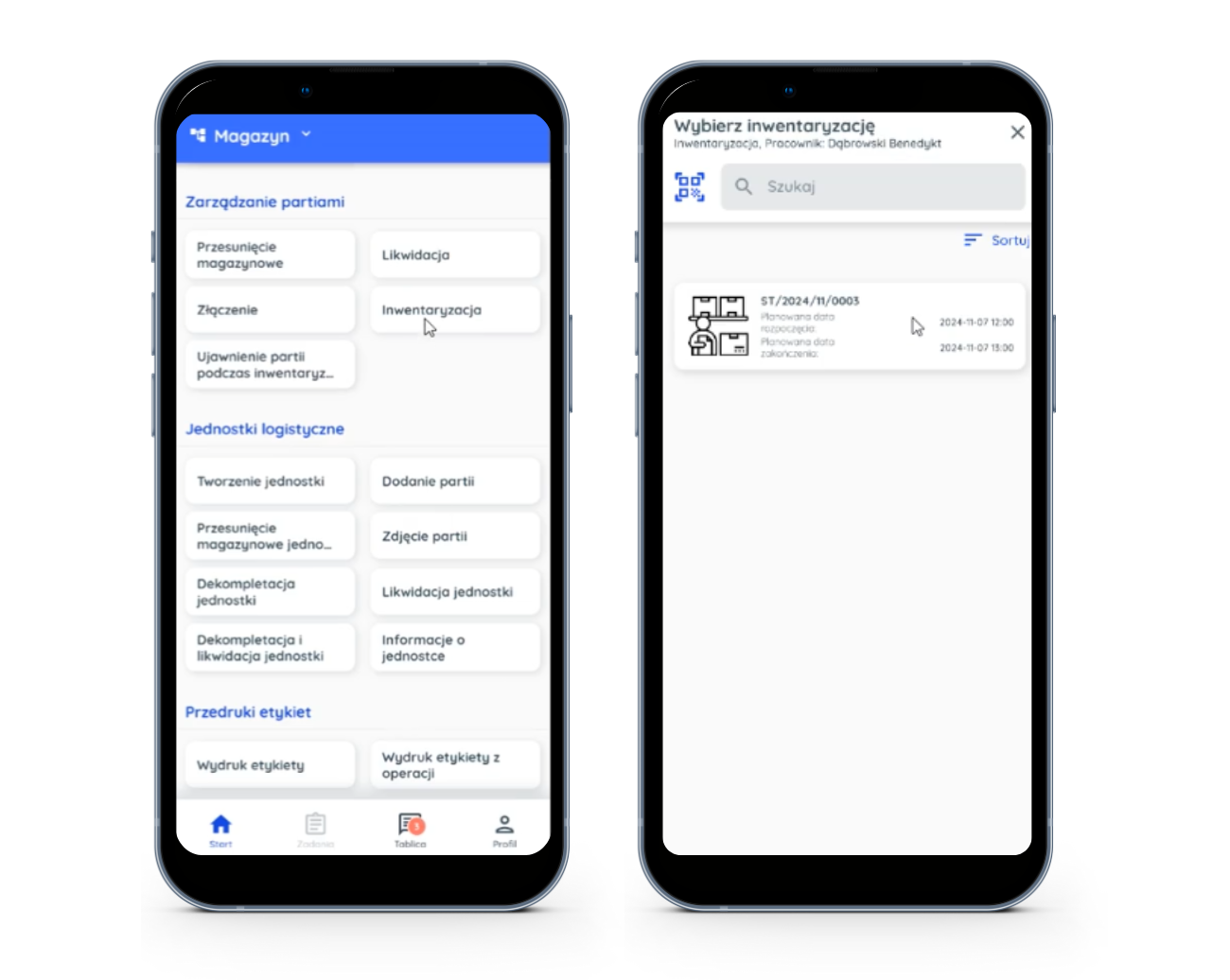

XPRIMER.WM provides full transparency in warehouse transfers, material withdrawals for machines, material returns from machines, material demand requests, and the merging, splitting, or disposal of batches of raw materials, semi-finished products, or finished goods.

This ensures better utilization of materials and semi-finished products while eliminating waste, as only the exact amount required to produce a specific batch is allocated to the machine.

Material allocation to production on specific machines and operations, along with material returns, allows for efficient management of work-in-progress. Users maintain full control over the movement and status of every material batch.

Ensure full control and up-to-date information on inventory levels

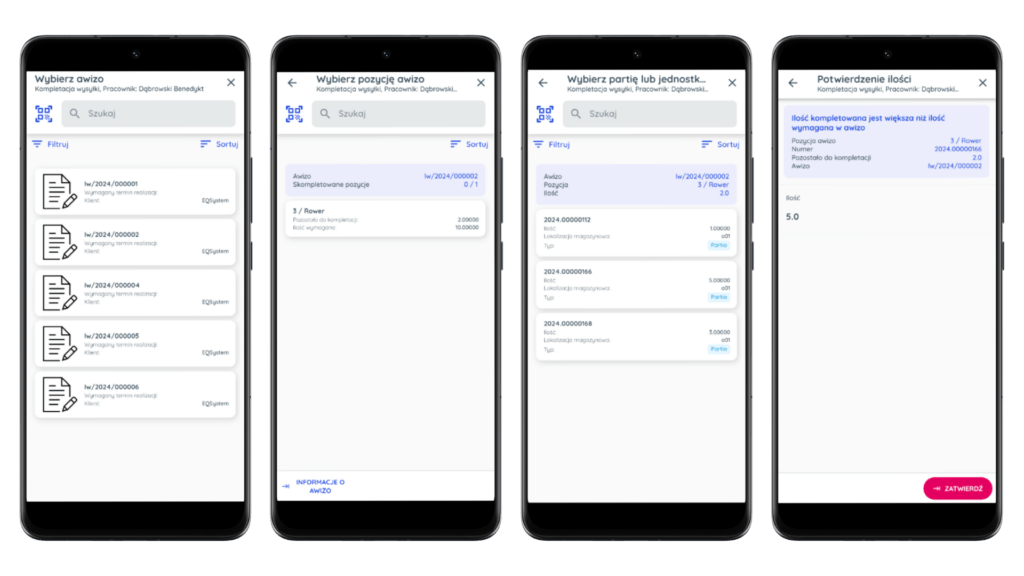

Streamline warehouse logistics processes for both uniform and mixed shipment orders.

Increase customer satisfaction with better timeliness and service quality

Gain access to detailed information impacting organizational costs

Monitoring warehouse flows and material movements in production enables precise tracking of the location of raw materials, semi-finished products, and finished goods at every stage of the production process. This allows for real-time calculation of work-in-progress (WIP) costs, facilitating the identification of areas requiring optimization.

Comprehensive records of all warehouse movements and material flows in production, combined with production tracking provided by XPRIMER.MES and full traceability through XPRIMER.TRC, enable the collection of data necessary to calculate the actual production cost. This empowers you to precisely control costs, reduce waste, and optimize production processes.

See how XPRIMER.WM works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.WM works.

Explore XPRIMER users reviews