XPRIMER.TRC - digital control of the product in accordance with traceability requirements

XPRIMER.TRC (traceability) allows you to record the relationship between manufactured products and consumed materials in your production process. This enables a detailed analysis of the materials used to produce any individual batch or what other batches contain the product.

The traceability provided by XPRIMER.TRC is crucial to guarantee the right level of product safety.

The XPRIMER.TRC module enables meeting regulatory requirements and customer conditions for product control at all stages of production, processing and distribution.

Rely on complete product information from XPRIMER.TRC

Increase production quality

through insightful analysis of each product component and its associated manufacturing processes.

Gain new customers

by meeting the terms for delivery and documentation set by the most demanding customers.

Solve problems quickly

with instant access to information collected in one place.

Reduce costs

through real-time recording of production

in progress and stock levels as well as information on actual material consumption.

Improve customer service

by having access to full knowledge of product components and batch distribution.

Increase productivity

by making optimal use of the production capacity identified in the MES system.

See how XPRIMER.TRC works in practice

Contact us and arrange a meeting, during which we will demonstrate how XPRIMER.TRC works.

Zobacz, jakie korzyści uzyskali nasi klienci dzięki wdrożeniu XPRIMER.TRC

Przeczytaj historie klientów, którzy z nami usprawnili procesy produkcyjne.

Explore the functionalities of XPRIMER.TRC

Make sure that your customers and your brand are properly protected

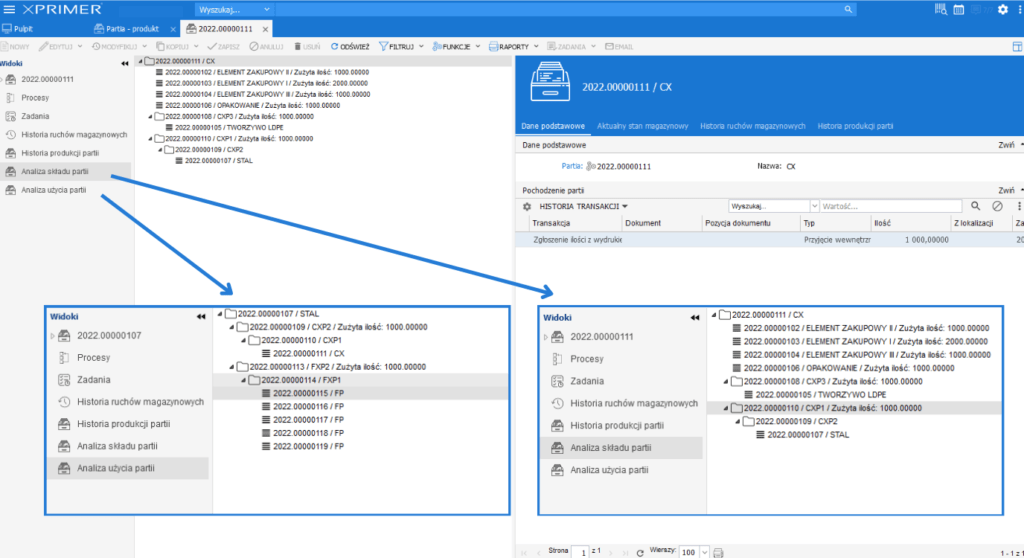

XPRIMER.TRC enables recording and tracking the genealogy of raw materials, production in progress and products introduced to market in compliance with regulatory requirements binding for multiple industries. Traceability data available in real time enable proactive prevention of quality problems even before the product is shipped (e.g., by blocking certain batches).

XPRIMER.TRC provides the ability to trace goods and raw materials backward through the supply chain or forward through the distribution chain. It eliminates paper documentation and provides access to information within seconds

Gain complete insight into the flow of goods and materials

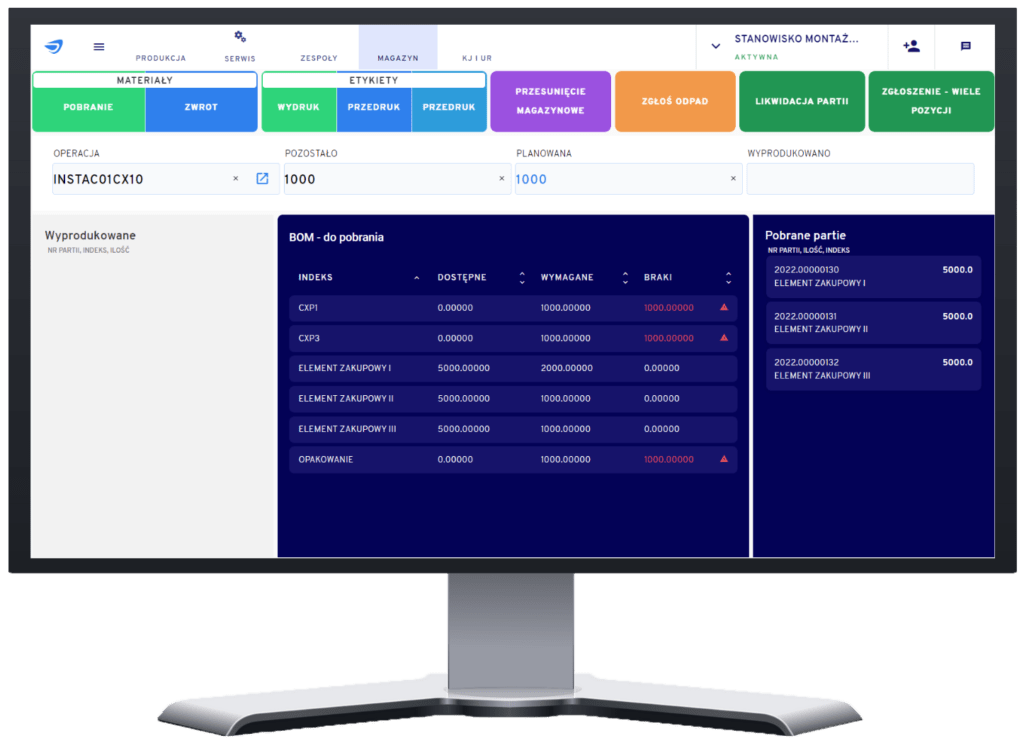

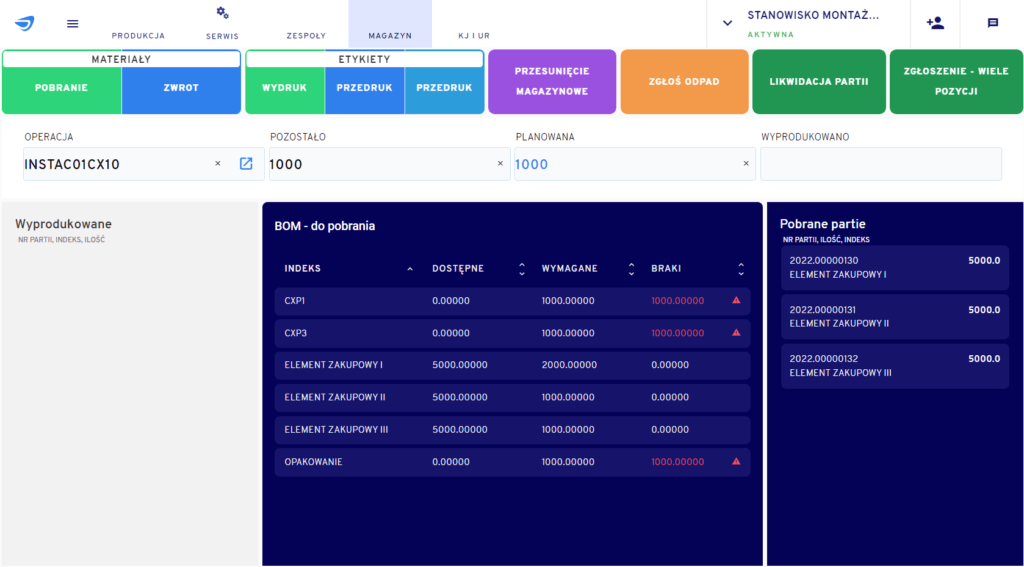

XPRIMER.TRC allows you to carry out the traceability of the process and the genealogy of the product with accuracy to a single batch or even individual unit. It allows you to track the necessary parameters, such as production date and time, part serial number, operator ID, station identification, operation number, production plant number, registration of process parameters (as needed for individual operations), identification of the sequence of processes and BOM registration.

The detailed connection of the batch of material used with the manufactured product enables precise calculation of the actual production costs.

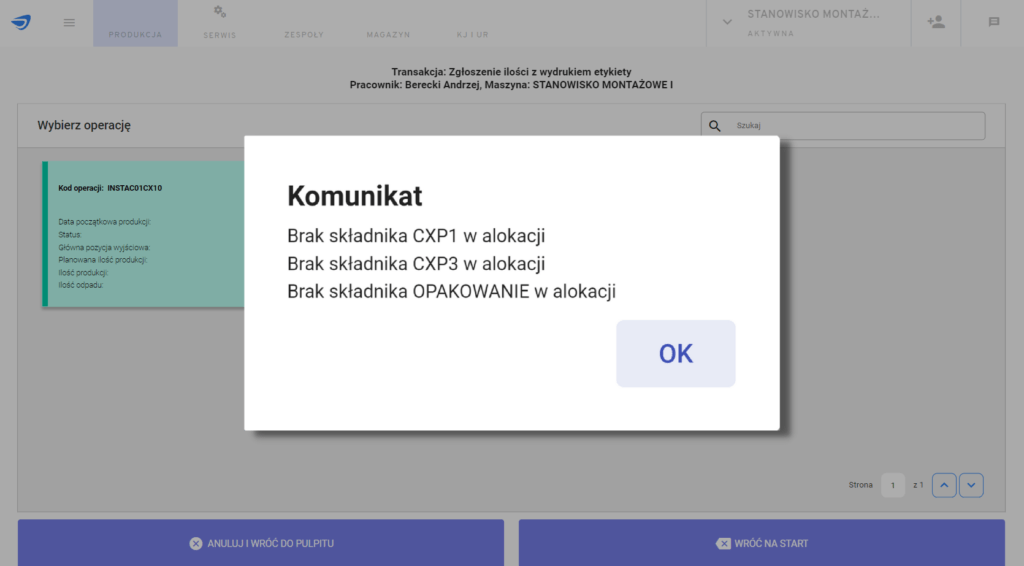

Reduce the risk of errors with advanced control measures

The validation mechanisms included in XPRIMER.TRC prevent errors in recording the use of materials. The system requires the operator to indicate the specific batch of materials used and verifies the accuracy of the provided data. The use of RFID or barcode technology not only makes work easier, but also minimises the risk of error.

In addition, XPRIMER.TRC comprehensively monitors all incoming, stored and outgoing goods as well as the processes to which the products are subjected and thus ensures that the final product contains all required components and follows all planned processes.

Use information to better manage production

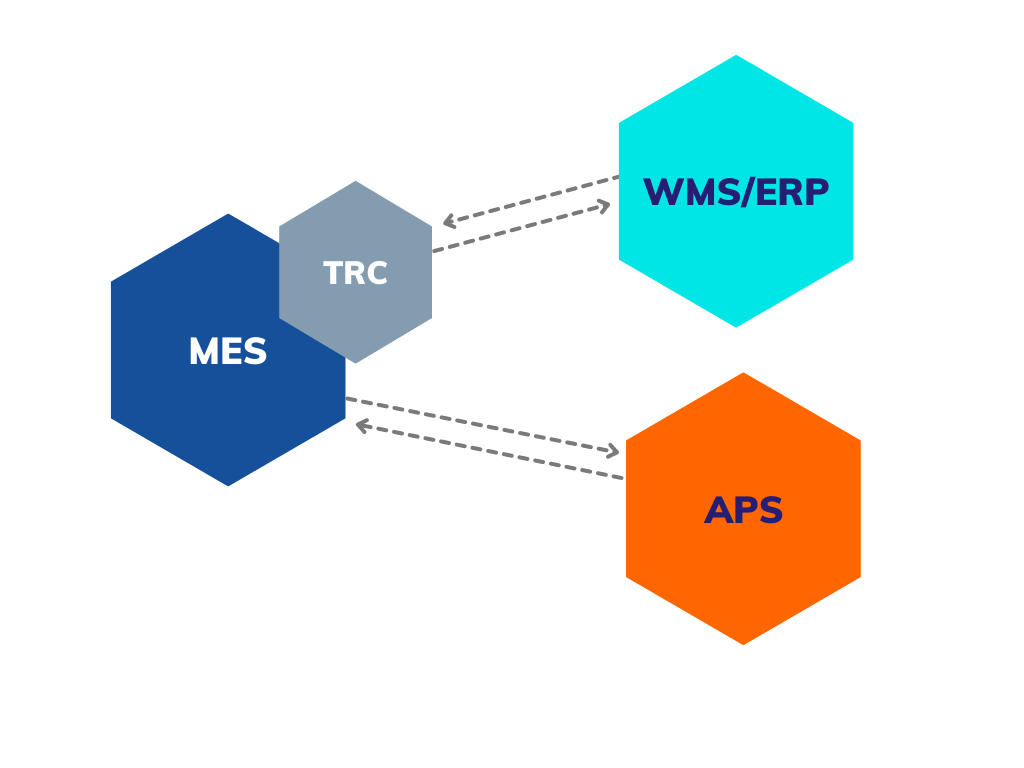

XPRIMER.TRC, as a component of the MOM production management platform, ensures free flow of information between other management systems (including WMS/ERP and APS), thus improving the quality of production plans.

The historical and real-time data available in XPRIMER.TRC allows for more precise analysis to further optimise processes and make better decisions.

See how XPRIMER.TRC works in practice

Contact us and arrange a meeting, during which we will demonstrate how XPRIMER.TRC works.

Explore XPRIMER user reviews