XPRIMER.TCW - a comprehensive repository of technological data available online

XPRIMER.TCW (Technology Creator Wizard) is a specialised tool that gives complete autonomy in technology management – the user decides which elements should be used to build them.

Complete discretion in technology management as well as flexibility and speed in the building of routes and BOMs in XPRIMER.TCW allows a precise description of the production process.

Technology management in XPRIMER.TCW enables not only the reflection of the actual production process, but also all the constraints that should be taken into account in the planning and scheduling. This makes XPRIMER.TCW the ideal tool to complement the ASPROVA APS production planning system.

Streamline production processes through proper technology management in XPRIMER.TCW

Improve planning accuracy

enhancing the quality of technology data and reflecting all elements in the technology, including operation times, buffers and relationships between processes and all constraints.

Combine production and accounting needs

by having the data available both for cost accounting in the ERP system and to reflect the actual technological processes for production.

Decrease process data preparation time

creating new technologies efficiently based on predefined templates and ready-made components.

Plan production costs

by using information on the consumption of materials, semi-finished products, utilities and labour and machine-hours contained in the technologies to calculate the technical cost of production (TMC).

Increase operational flexibility

by creating new technology variants with alternative resources, product substitutes and alternative routes.

Reduce the number of errors

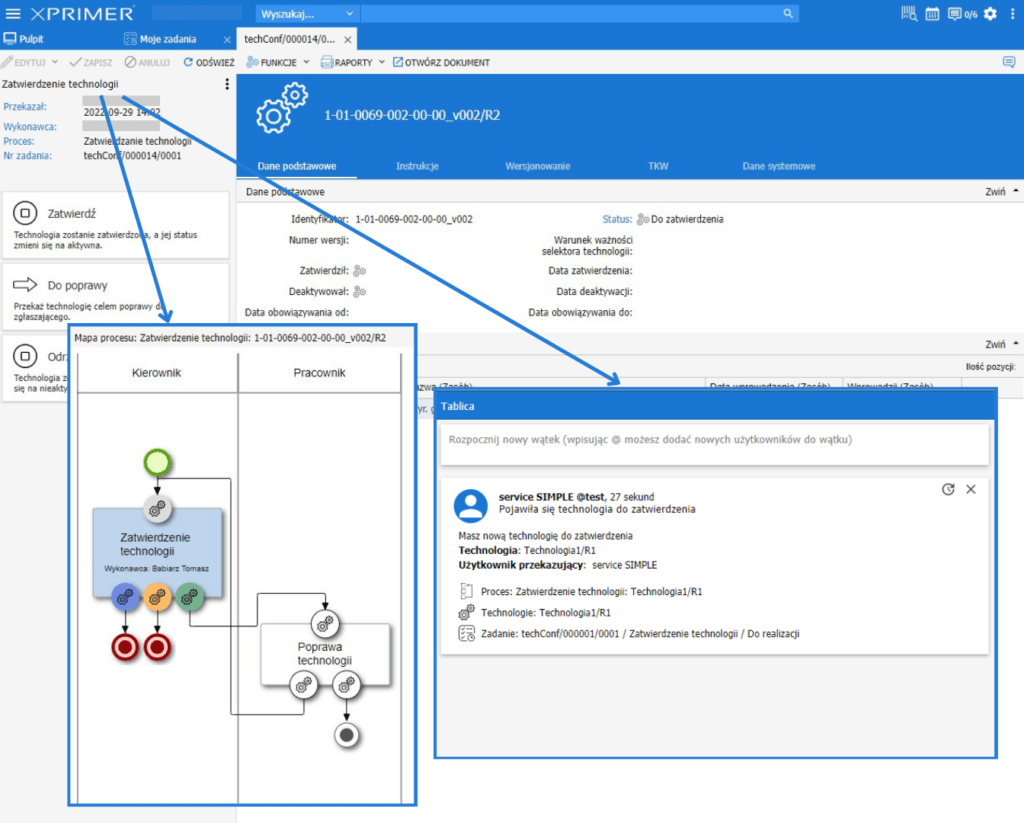

through an established technology acceptance path and the use of validators, where the system verifies the data's completeness.

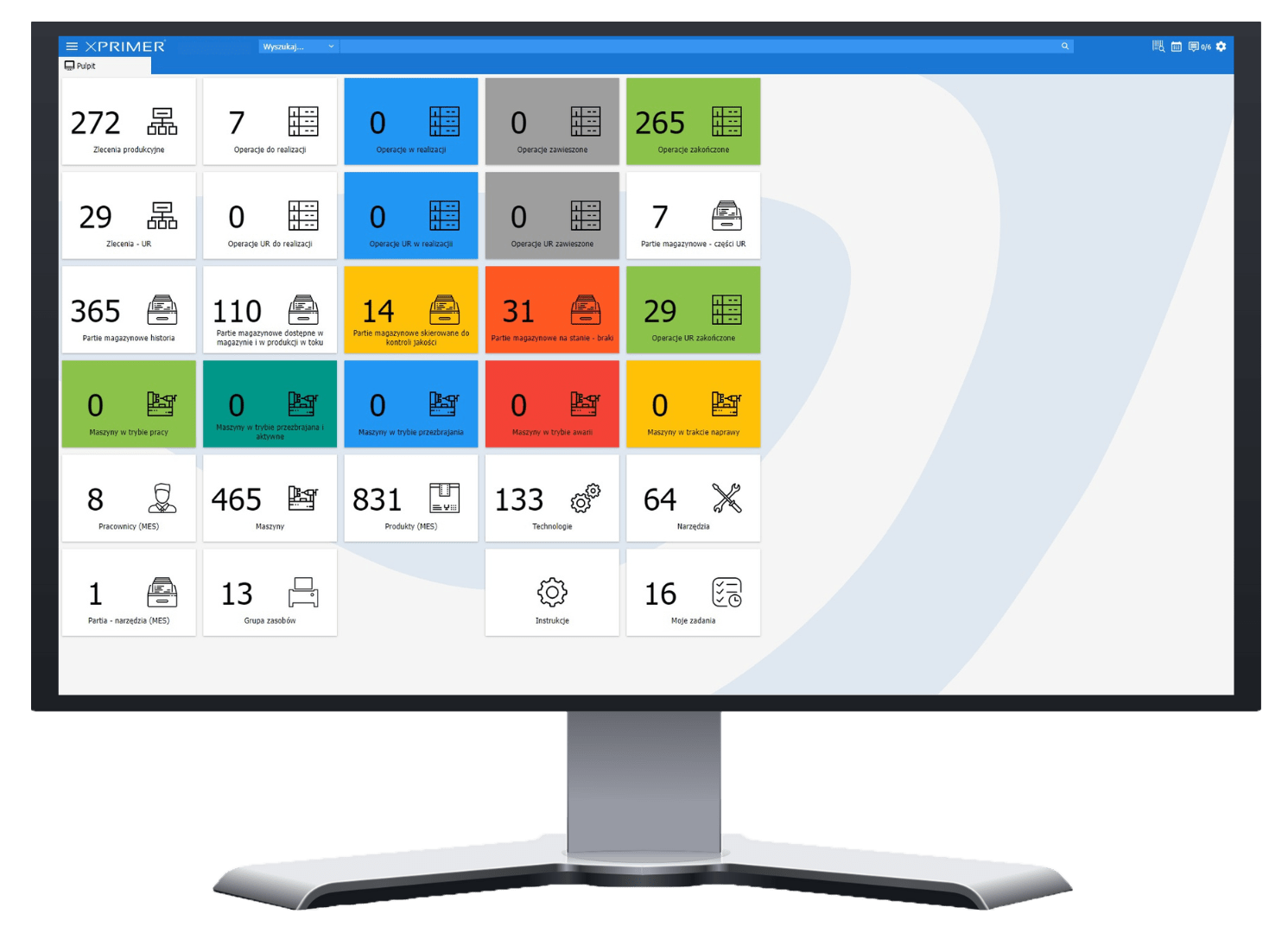

See how XPRIMER.TCW works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.TCW works.

Explore the functionalities of XPRIMER.TCW

Include all the details of your production processes in the technologies created

XPRIMER.TCW allows to reflect the actual production process with all its details.

The creation of a new technology is possible from scratch or using a predefined template, or based on an existing technology.

Each technology can include elements such as:

- resources and alternative resources, together with performance standards,

- number of operators necessary to perform a given operation,

- tools and alternative tools (e.g. moulds, tooling, dies, punches) with an indication of their quantity,

- raw materials, components, semi-finished products,

- unit operation times, whole batch execution times,

- changeover times and changeover matrixes,

- preparation times and completion times,

- limitation of minimum and maximum times between operations,

- relationships between operations,

- any other process and organisational constraints.

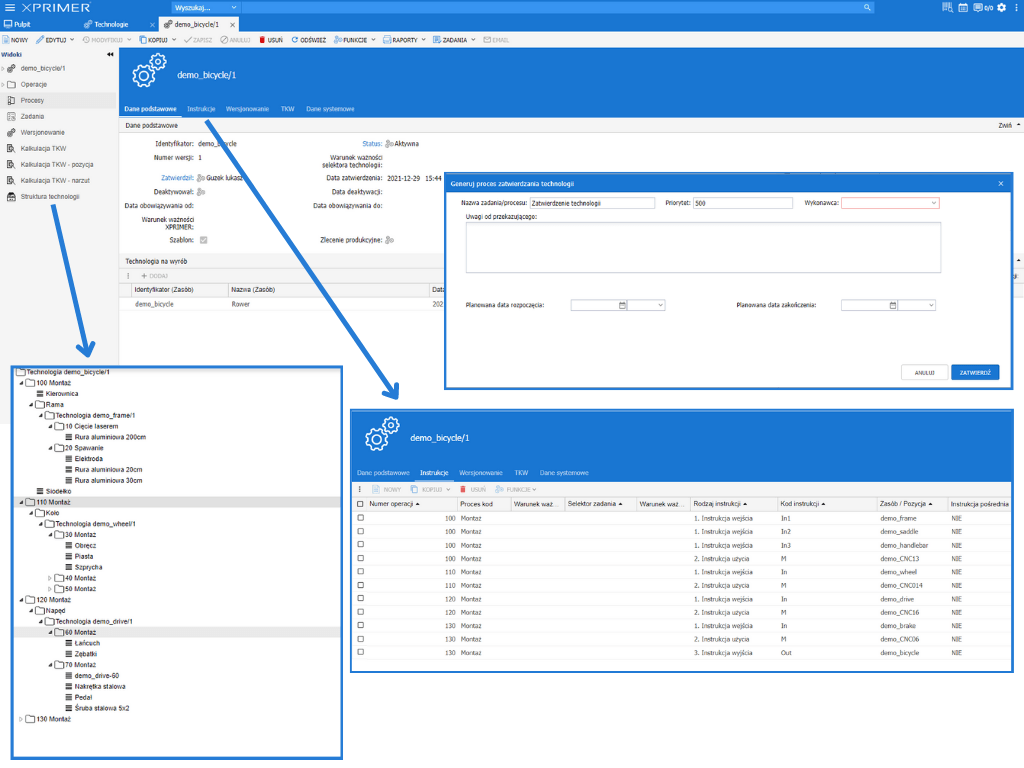

The tree structure view of products and technologies in XPRIMER.TCW allows easy viewing of BOMs and facilitates verification of the technology description for each BOM item.

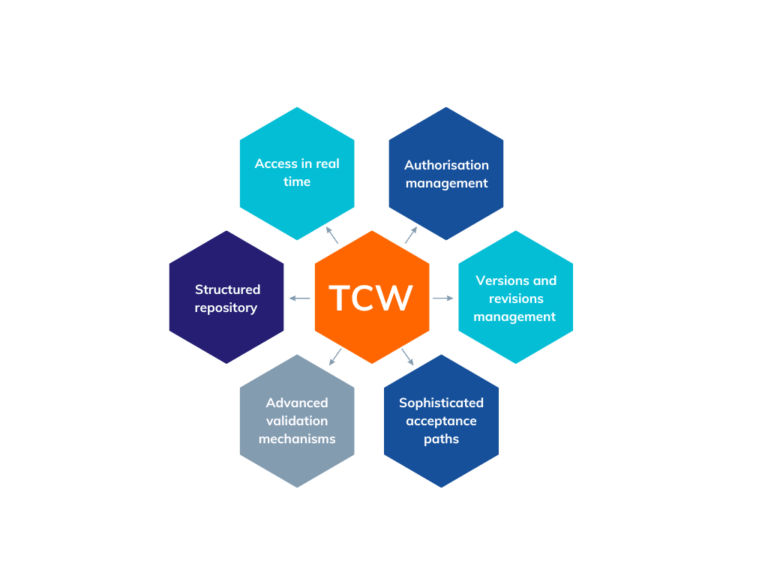

Ensure data security and full control of technologies stored in one place

XPRIMER.TCW gives complete discretion in the management of routes, recipes, required resources and additional parameters that describe the process. Most importantly, all this structured data is stored in one place and accessible online.

An extensive authorisation management system increases data security by defining the users who can create, modify or approve technologies.

Supervise technology versioning and create alternative technologies

XPRIMER.TCW enables the management of versions and revisions of defined technologies. It allows to view the changes that have been made at the various stages of building, creating and updating technologies, with detailed information on by whom and when the change was made.

In the approval process for technological data, XPRIMER.TCW uses a defined approval path.

XPRIMER.TCW also offers the possibility to create technologies for specific product groups or alternative technologies when a given product can be obtained through a different production process or by using different raw materials.

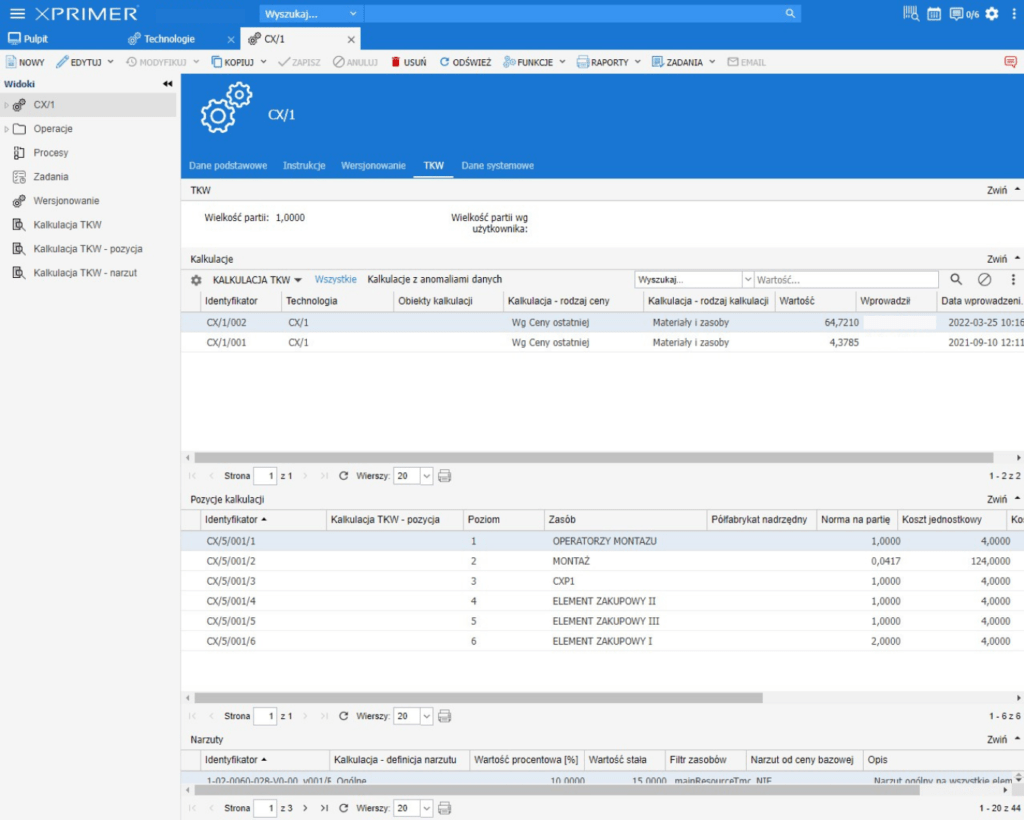

Precisely calculate the technical manufacturing cost (TMC)

Within the XPRIMER platform, it is possible to use a tool for determining the Technical Manufacturing Cost of a product (TMC). It allows to configure calculating formulas on the basis of product/semi-finished product manufacturing technology, taking into account, among others, operators’ man-hour rates, machine-hours, material and raw material price variants and surcharges. The user can influence the algorithm for calculating the technical manufacturing cost by creating their own calculation methods, defining surcharges or taking additional variables into account.

XPRIMER provides access to always up-to-date data and allows for:

- calculate the technical manufacturing cost,

- define surcharges for the calculation,

- define calculation templates including parameters and surcharges,

- calculate TMC for various material index prices (taking into account many variables, e.g. considering average, last, maximum, inventory, user or calculation prices),

- creation of single- or multi-level calculations,

- creation of independent calculation methods or use of existing ones.

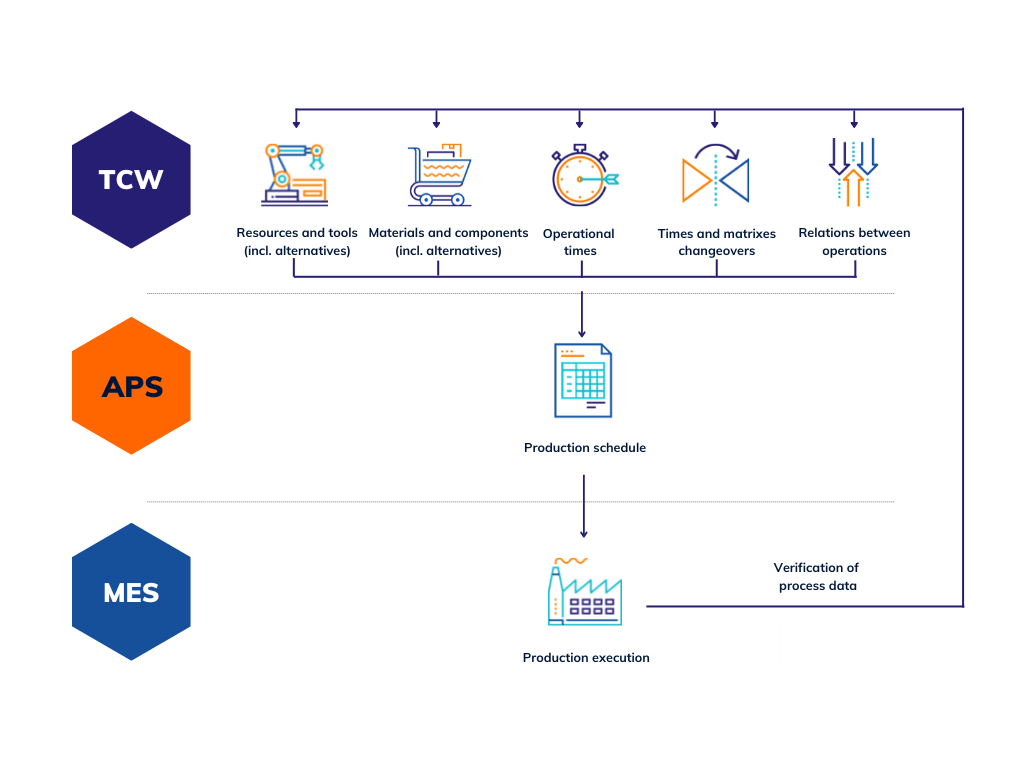

Optimise production processes by integrating data between different systems

The combination of the data flow between the ERP system and XPRIMER.TCW allows the creation of a single repository responsible for the management of technological data, meeting the requirements of both the accounting and production departments.

All the detailed technological data contained in XPRIMER.TCW is used to create production plans and schedules, implemented in the APS system. This ensures that you have complete data for production planning and scheduling. XPRIMER.TCW gives you the opportunity to include in the plans all the necessary information on the production process flow, resources, alternative resources, tools, process constraints, changeovers and times required for individual activities.

The combination of the tools offered by the eq system into one coherent ecosystem allows you to control whether your technological data have been correctly defined. The execution and recording of production progress in the XPRIMER.MES system provides real-time information on whether the assumptions made about performance standards and the production process flow were correct.

See how XPRIMER.TCW works in practice

Contact us and arrange a meeting, during which we will present how XPRIMER.TCW works.

Explore XPRIMER users reviews