ASPROVA APS – a solution for problems with production planning and scheduling

ASPROVA APS (Advanced Planning and Scheduling) is a specialised system designed to improve production management processes, particularly in the areas of production planning and scheduling.

With a single click, ASPROVA APS generates a plan that takes into account the complete production logistics and ensures a smooth flow of materials and information.

ASPROVA APS is a solution which, thanks to its flexibility and wide possibilities of development (also customer-based) ensures to meet both current expectations and those that will appear in the future.

Choose advanced planning and scheduling with Lean Production support

Shorten your production cycle

by reducing downtimes

and minimising breaks between processes.

Increase production flexibility

by being able to quickly modify plans according to changing market conditions.

Reduce stock inventory

by being able to see precise demand dates in production logistics.

Increase productivity

by better synchronisation of processes and better use of resources.

Improve performance timeliness

by creating precise and realistic production plans, taking into account all process limitations.

Optimise resource utilisation

by having a complete overview of the planned load for your production assets.

Extend the planning horizon

by using a quick response system

with a properly organised database

Reduce production in progress

by continuous monitoring of the availability

of materials.

Design production capacity

by simulating different planning options.

See how our customers have benefited from implementing

ASPROVA APS.

Read stories of customers who have streamlined their manufacturing processes with us.

Explore the functionalities of ASPROVA APS

Create realistic and feasible production plans

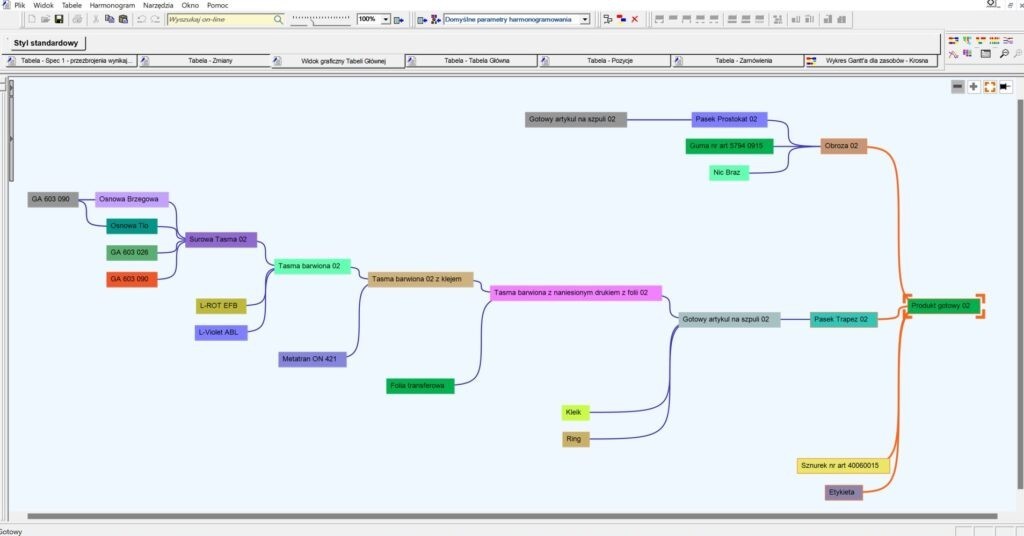

Any production schedule must be realistic and feasible. There are no states in between: it is either correct or wrong. ASPROVA APS uses precise mapping of all production processes and constraints to generate the best schedule.

With ASPROVA APS, you can apply multi-level planning, taking into account all resource and process bottleneck, actual stock available and orders. This is made possible by the vast number of parameters used in advanced scheduling algorithms.

Plan in a system that reflects 100% the specifics of your plant

ASPROVA APS enables you to accurately reflect your process with all its details. In ASPROVA APS, you can capture the specific properties of individual production processes, independently define any optimisation criteria and the relationships between operations in areas such as

- production technology,

- relationship between the different tasks,

- production tools and their availability,

- employee competences,

- resource parameters, product and raw material parameters,

- maintenance.

Quickly adjust production as changes occur

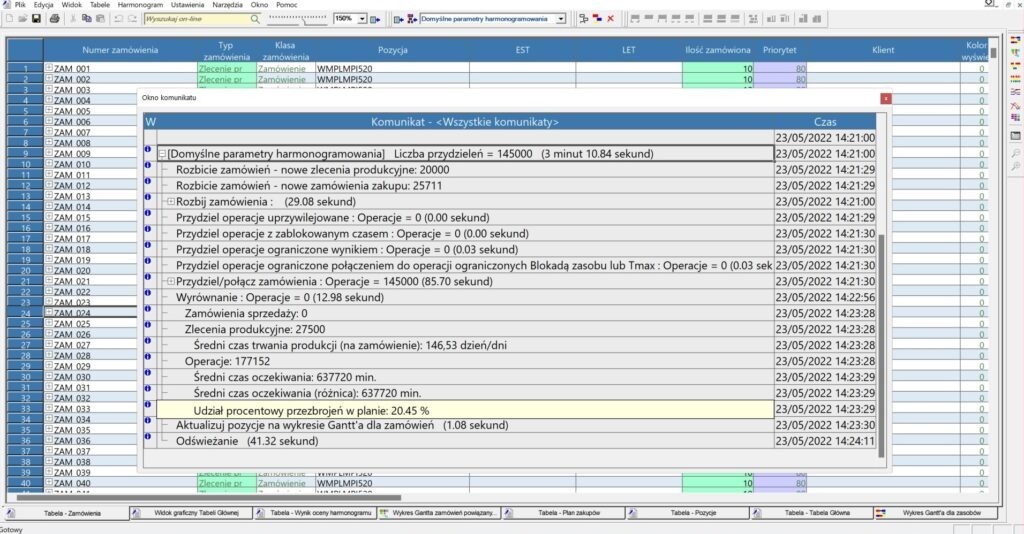

The great advantage of ASPROVA APS is the unparalleled speed built on carefully developed and highly efficient algorithms used to quickly create realistic and feasible production schedules. This gives you the ability to instantly update your schedule to reflect your current situation.

The computational performance of 5,000 operations in 3 seconds and 100,000 operations in few minutes, taking into account more than a thousand parameters for each production order, positions ASPROVA as the world’s fastest production planning system.

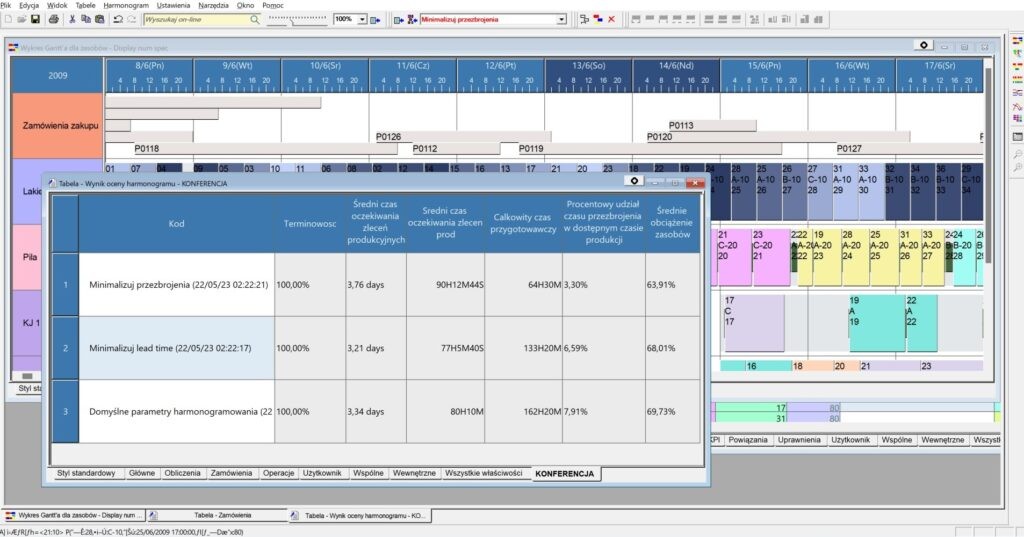

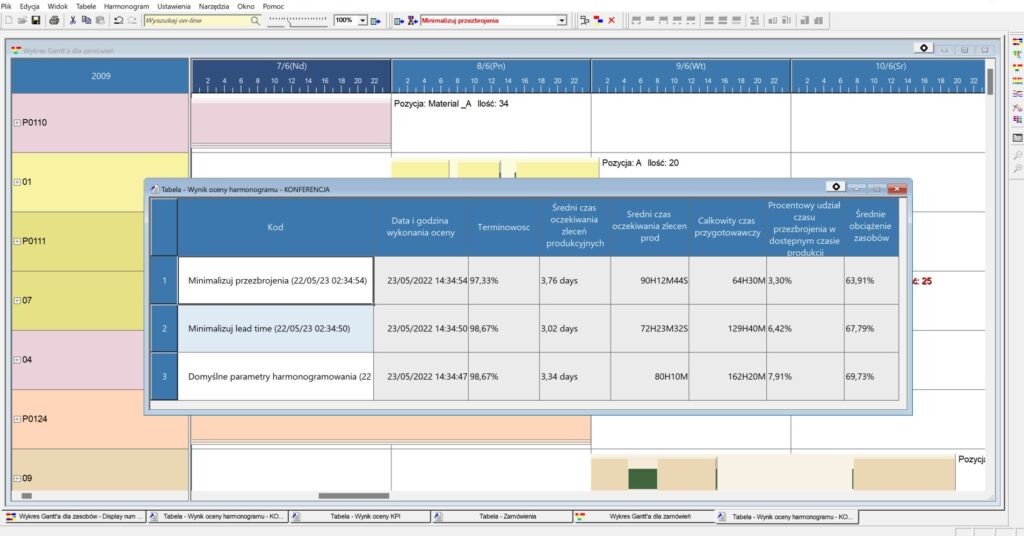

Run simulations and select the most appropriate production plan scenario

ASPROVA APS gives you the ability to quickly create detailed what-if simulations. Cost, lead time, stock, potential bottlenecks and many other factors are taken into consideration. With simulations, you can easily compare different schedule options, production planning methods and the effects of potential changes. Safely select the ones that best fit your company’s current business goals.

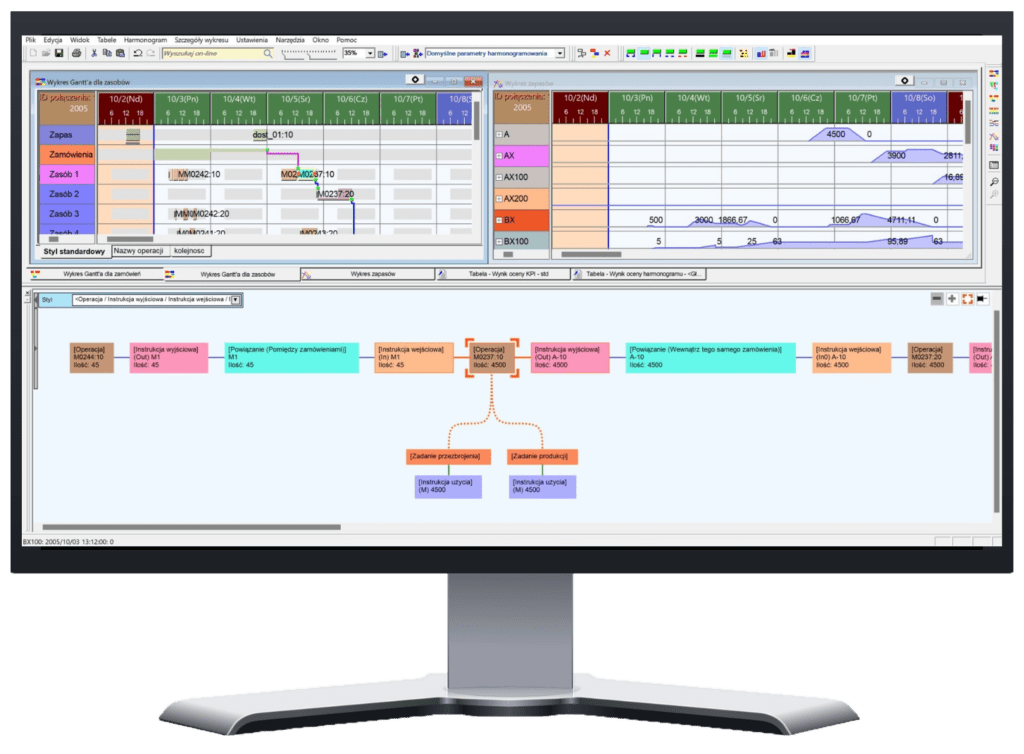

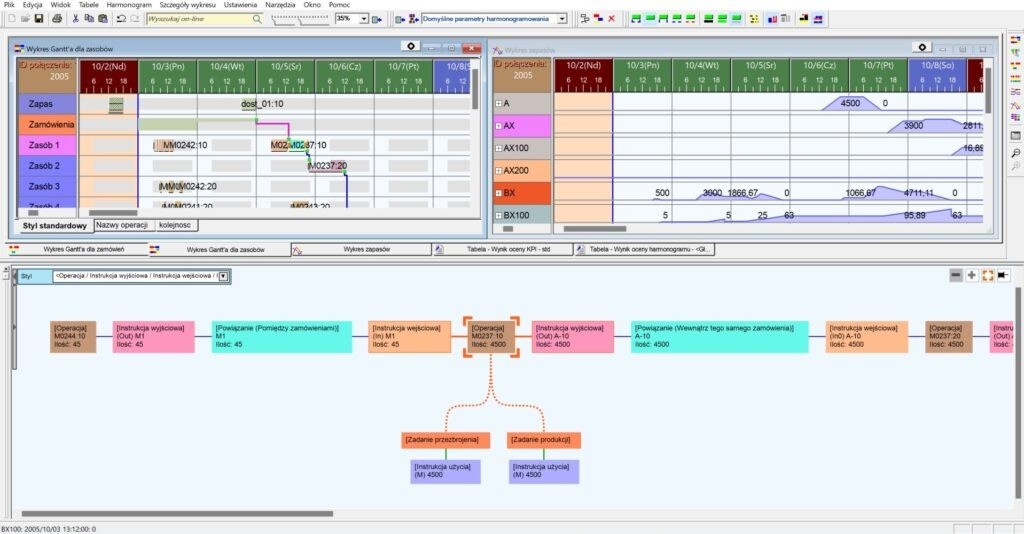

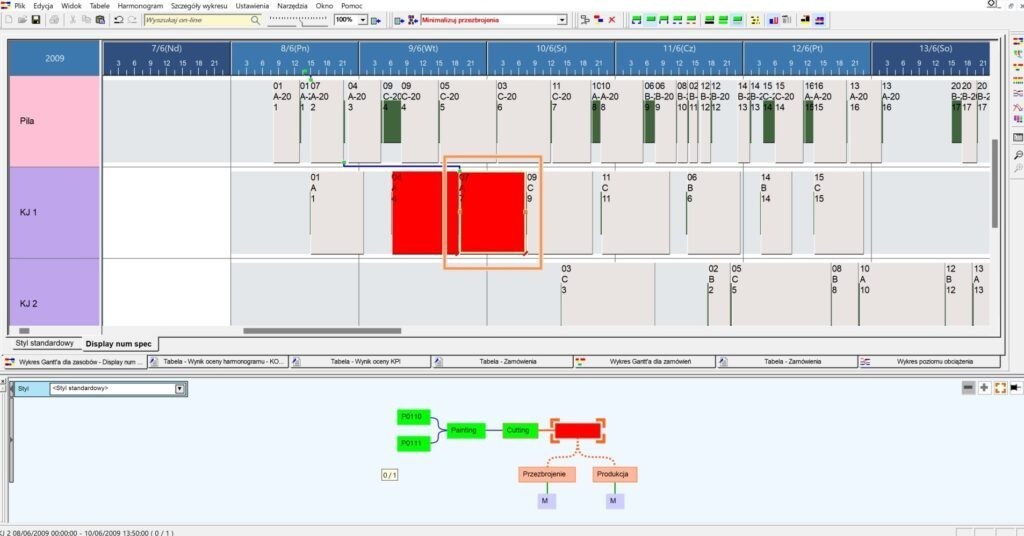

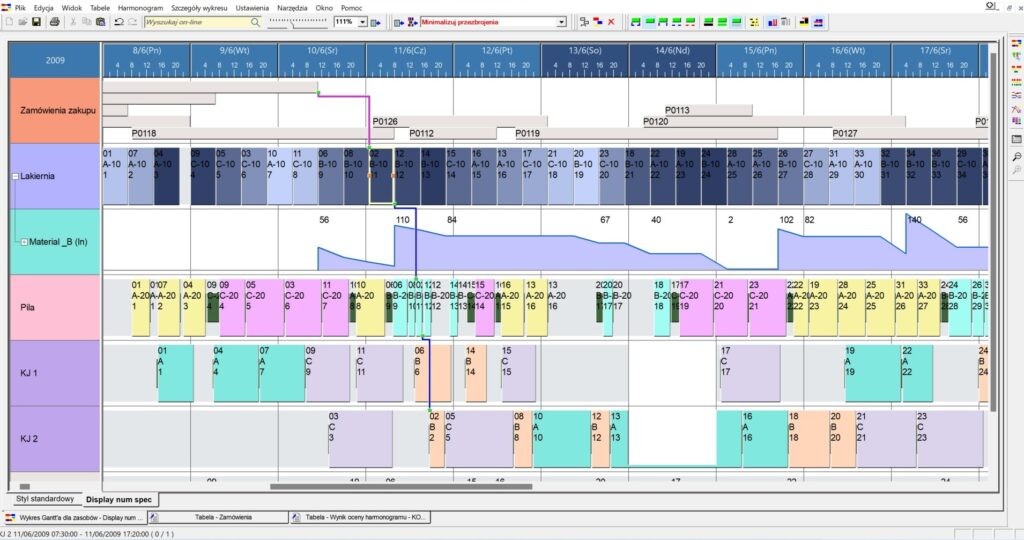

Quickly assess the situation with clear visualisation

The visualisation tools in ASPROVA APS allow you to identify bottlenecks and potential risks well in advance, so you can take the necessary preventive action.

The result of planning is presented in the form of a Gantt diagram, containing the overall representation of all activities that make up the performance of the production order. The layout of the diagram allows observation of both ongoing and future production. Clear visualisation of the entire process and data aggregation capabilities allow you to see much more and much faster. Graphical user interface allows you to customise your data views to suit your preferences.

Monitor and revise production schedules based on KPIs

ASPROVA APS gives you the ability to evaluate your production schedule against selected Key Performance Indicators (KPIs).

KPIs are calculated for the entire plan or for individual orders, resources or products. Comparison of KPIs for individual plan options enables assessment of: turnover, costs, profits, timeliness, lead times, production cycle length, downtimes, share of changeover periods in the cycle, quantity and value of stock, etc.

ASPROVA APS uses approximately 100 financial and organisational KPIs that are all individually configurable. They are also successfully used for schedule simulations.

Apply Lean Management and Kaizen best practices

ASPROVA APS was developed in close cooperation with leading Japanese manufacturing companies from all sectors of the industry. Our continuously improved system fits well within the principles of Lean Management methods and techniques.

With the help of ASPROVA APS, it is possible to take actions in line with the Kaizen philosophy (continuous improvement) and check what impact they will have on the results, including the efficiency of the use of individual resources and the productivity of the company.

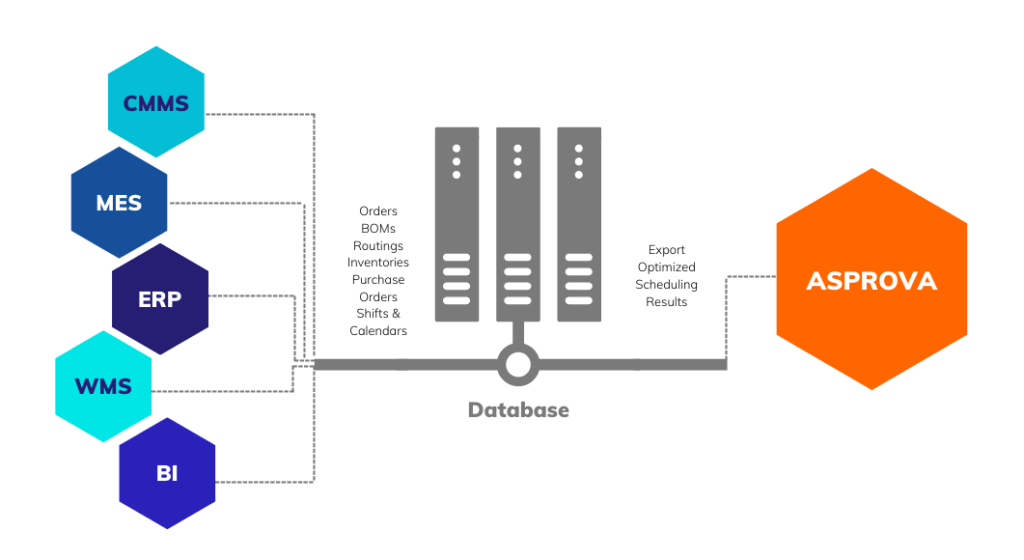

Adjust the parameters of the system yourself and ensure seamless data exchange with other IT systems

No programming is required to implement ASPROVA APS, as 99.9% of the settings can be adjusted by configuring standard program parameters. The user alone is able to maintain the system, develop it, and build scheduling functions. The parameters for all elements are accessible from the user panel.

The system’s interface tools allow for easy connection to any external systems (including ERP, WMS, MES, CMMS or BI).

See how ASPROVA APS works in practice

Contact us and arrange a meeting, during which we will present how ASPROVA APS works.

Explore ASPROVA APS user reviews