The correct flow of information is a key element in any company – no matter where we are in the organisation and no matter what process we are talking about. Whether in the production cycle or any other, the basis of an organisation’s operations is the availability of information and its efficient exchange.

Communicating all areas of a company’s operations with each other is often the key challenge from which we start process improvement. The problem repeatedly identified by our clients is inadequate communication, a lack of information or an excess of information (unselected information) and delays in getting this information to the right person.

The same problem applies to the management of maintenance services. This organisational unit, as the name suggests, is responsible for ensuring that equipment and machines are constantly in motion, but the maintenance service employees also remain in motion. No one sits in an office waiting for an assignment to appear; often, a maintenance service employee does not have time to sit down at a company computer for hours or even days. Their primary working tool is becoming a mobile phone or tablet.

Mobility with XPRIMER.CMMS

XPRIMER.CMMS has been designed to actually support maintenance service technicians, rather than adding extra work associated with the system. Knowing that the maintenance worker always has his or her mobile phone with them, a mobile application was developed that provides immediate access to information, both for the maintenance technician and for his or her supervisor, who manages the entire team.

When the machine operator reports a breakdown or fault on the production terminal (in the case of integration with XPRIMER.MES, this information is exchanged automatically), the information goes to the person managing the work of the maintenance team – it appears directly on his or her mobile phone.

The XPRIMER.CMMS mobile app displays a message to the manager of the maintenance services on the mobile phone in the form of an SMS, email or push-up message (analogous to WhatsApp or Messenger). Why so many ways of sending information? It is because in the case of events requiring an urgent response, there is no way that such a message will not be delivered immediately to the person responsible for the distribution of service tasks. In order to exclude problems with, for example, Internet access (which can occur on the production floor), messages are also sent via SMS.

In the message about a specific service request, the maintenance manager receives information about the object of service, the reason and type of request and its priority. In the case of a request already entered in the mobile app, attachments, such as a photo of the fault, may also appear.

Based on this data, the maintenance manager assigns the request to a specific technician, who receives a message on his or her mobile device about the assigned request.

Each user of the mobile app can view a list of all service requests, indicating their priorities and statuses.

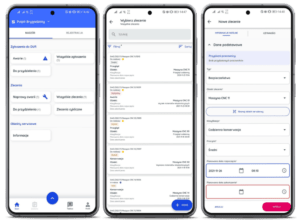

screens of the XPRIMER.CMMS mobile app

The employee assigned to a service request in the mobile application can decide whether to accept or reject the request. Before the request is accepted, there is a physical verification of the registered problem by the maintenance technician. During the verification, the technician has the option to define the repair path by selecting the classification of the request, specifying repair actions and providing the planned start and end date of the repair action (a feature of the XPRIMER.CMMS mobile application is the possibility to use order templates when entering an order). What is interesting – in the case of critical requests, there is the functionality to enter confirmation that the maintenance employee has actually been at the site of the machine, e.g. by scanning its QR code. The employee at this stage can also enclose attachments, e.g. photos of the fault. Once the request is accepted, a service order is generated.

Every action that is carried out in the mobile application is recorded in a database (e.g. the time it took for the maintenance department to take action, the time the maintenance department arrived at the machine, etc.). This allows the building of a knowledge base of the maintenance/repair activities undertaken and the calculation of indicators relevant to the assessment of the effectiveness of maintenance services (MTTR – mean time to repair, MRT – mean time to respond, MTTF – mean time without failure of the machine and MTBF – mean time between failures). This has the long-term effect in reducing the non-availability time of a resource and thus increasing the productivity of the plant.

An employee who undertakes a service order from his or her phone and the mobile app installed on it verifies the assigned materials, parts and activities that should be performed in the execution of the repair. Here, he or she can also record the time worked on the task. When the ‘Start’ button is clicked, the status of the repair object order is changed and the technician’s working time is recorded.

Within a given service request, the technician performs predefined repair activities. During his or her work, he or she can verify in a predefined list that all these activities have been carried out and record the consumption of parts and materials used for the repair (by selecting them from a list or by scanning the barcode).

When the repair activity is completed, the completion of the work is recorded by clicking the “Finish” button. At this point, the technician can attach the repair documents, photos of the fault removed or the part replaced, and indicate whether the machine can already be unlocked for production.

Preventive measures

The XPRIMER.CMMS mobile app also allows the management of overhaul activities and periodic orders, which are the basis of a preventive strategy.

The overhaul and maintenance activities plan itself is created from the desktop. Here, a rush is not recommended. Creating consistent overhaul plans requires a high degree of precision in decision-making, and the use of information from other IT systems (e.g. from the planning area) allows overhaul plans to reflect the priorities of production plans. Plans can also be defined ahead of time within a specific time frame and consider planned production interruptions (e.g. holiday breaks, Christmas breaks, etc.). Until the overhaul plan is accepted, it is not displayed in the mobile application.

On the other hand, once the overhaul plan is accepted, individual maintenance orders in the form of service inspections or maintenance activities are made available to the head of the maintenance department, who assigns them to individual technicians.

There is also a feature of automatic generation of maintenance orders in the case of periodic tasks. In such a situation, once certain predefined machine parameters are exceeded (e.g. operating time, quantity produced on the machine, etc.), the system automatically generates a maintenance or overhaul order, which is placed on the list of service orders to be forwarded for execution.

Further, the procedure for processing service orders from the XPRIMER.CMMS mobile application looks similar to the procedures in the case of reactive activities.

An efficiently operating CMMS system is a tool that increases the availability of resources and thus increases company productivity. However, we should remember that the system is operated by people. Even the most advanced CMMS will not result in increased productivity if it is difficult and not intuitive to use. Only a tool that is comfortable for maintenance employees to use will be able to translate into real benefits for the company. In my opinion, the XPRIMER.CMMS mobile application is a guaranteed way to achieve this.

advisor of the Management Board of eq system

Would you like to find out how XPRIMER.CMMS will improve the work of maintenance services in your company and increase productivity? >>> Contact us